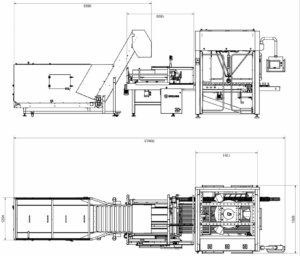

Robotic bottle sorter (unscrambler) – ANY bottle shape and size (transparent ones, colored and irregular), but NO FORMAT PARTS need. Automatic changeover of the sorting linear unit (depends on bottle size). Flexible and versatile production process, improved production capacity. The plant equipped with the unscrambler brings the productions to levels unattainable with manually operated lines (manual bottle insertion or cap placement).

The main features and advantages

(asymmetric): the visual verification system confirms the package is always the same- Supports a very wide range of packaging: from 30 ml bottles to 5 L canisters

- No formats parts: one format works with all type of bottles

- Automatic bottle change (on the operation panel)

- The robot can work with any production line supporting existing production in customer’s plant

- A simplified interface, utilizing the vision system, which not only allows you to easily change the format, but most of all allows the operator to add a new package type

- Can work with and without format nests (pucks)

- Productivity: 75 pcs/min (single robot) or 150 pcs/min (double ones)

[su_column size=”1/2″][video_popup title=”See the movie!” link_video=”https://youtu.be/lXImqf8Awn4″]http://unilogo.com.pl/wp-content/uploads/2016/12/Bez-tytułu.png[/video_popup][/su_column][su_column size=”1/2″][video_popup title=”See the movie!” link_video=”https://www.youtube.com/watch?v=fesUDONY3-8&t=1s”]http://unilogo.com.pl/wp-content/uploads/2016/08/ss.png[/video_popup][/su_column]