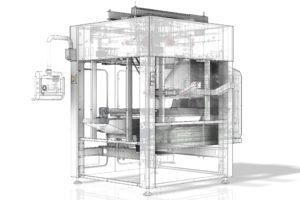

Robo Sorter 70

Robotic caps sorter

Capable of sorting many different cap types: triggers, pumps, screw-on caps, snap-on. Very few format parts necessary. This system resolves one of the main challanges of liquid filling lines – one automated device instead of many different sorters. Perfect for Private label manufacturers and all producers who deal with really wide range of differents products. Improved capacity and production process. Minimum changeover time. Less space needed – one device for all types of closures.

The main features and advantages:

- Supports each type of closure: triggers, pumps, snap-on, threaded caps.

- Works with different height of caps (e.g.: flat, shallow screw-on and high irregular triggers)

- No formats parts: one format works with all type of caps

- 3D vision cap inspection – reject of damaged caps

- HMI cap changeover (on the operation panel)

- The robot can work with any production line supporting existing production in customer’s plant

- Productivity: 75 pcs/min