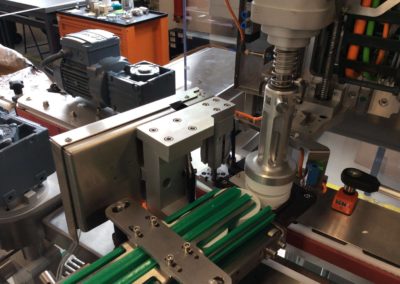

Linear device for non-stop capping – without stopping the packages and thus eliminating the risk of the medium splashing and achieving high productivity (up to 50 pcs/min for narrow packages for 2 heads).

Apart from classic twist-off closures, pull-push and flip-top may also be capped. Easy changeover (belts and easily exchangeable format elements: grippers and belt slippers).

The challenge:

The challenge we faced was connected mainly with the package (glass packages of 750 ml and 400 ml):

- Material and package shape:

an oval jar – hard, invulnerable to being pressed by guiding belts causing their damage, like spreading and clearances. The oval shape sets packages in any orientation hindering repeatable feeding and belt-guiding.

A glass package also necessitates a tolerance in measurements: sometimes 2 mm wider, higher or narrower. - Problem with cap presence verification:

the difference in glass tolerance was so high that the fork sensor was not able to detect if the package had been capped or not (it was letting through packages without closures because they were of the same height as the capped packages). - Soft, delicate caps:

thin and flabby plastic which could easily get deformed during traditional capping process when collecting caps (lateral gripping).

Solution:

- we have additionally equipped the machine with a fibre optics sensor which detects contrast (verifies cap presence). The fork sensor, on the other hand, verifies jars capped unevenly.

- The guide belt has been lined with an elastic sponge and, thanks to this solution, it bends on the spot, depending on package measurement tolerance. The guide belt works also as a positioning entity, ensuring repeatable package feeding.

- the Z9 gripper has been equipped with a vacuum suction cup – sucking in the whole cap surface, rather than gripping it from the feeder.

If you are interested in similar solutions, please contact our Sales Department.