FLEXIPUCKER 40

Automatic packaging sorter that is a complementation of basic pouring line with manual feeding system.

USAGE: COSMETIC AND CHEMICAL INDUSTRY

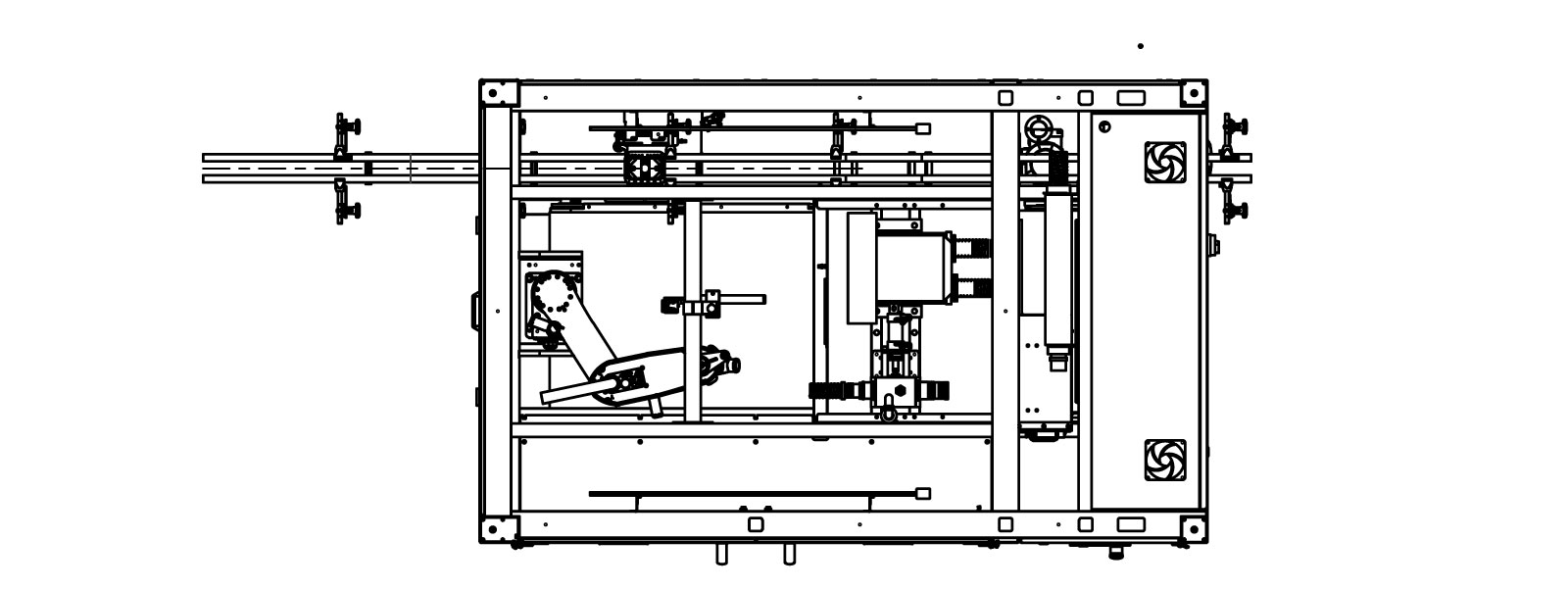

FlexiPucker 40 is an automatic machine, which improves the output capacity of every dosing line with manual packaging feeding. Due to compact dimensions, it can be installed even in small rooms. Device is equipped with SCARA arm, by means of which it collects the packaging from separate container. Then it verifies theirs placement on the conveyor and after that the arm with vacuum gripper carries and places the components in pucks or on the conveyor belt of machine located nearby. Vacuum grabbing system is more delicate than the mechanical one and because of that it does not damage the packaging. Machine can serve many types of components (including the bottles and jars, cylindrical and conical ones). Due to illumination in visual system, not only the shapes are being distinguished (also non-symmetrical ones), but also the colours and transparent packages are differentiated.

TYPES OF PACKAGING:

MAIN ADVANTAGES AND FEATURES:

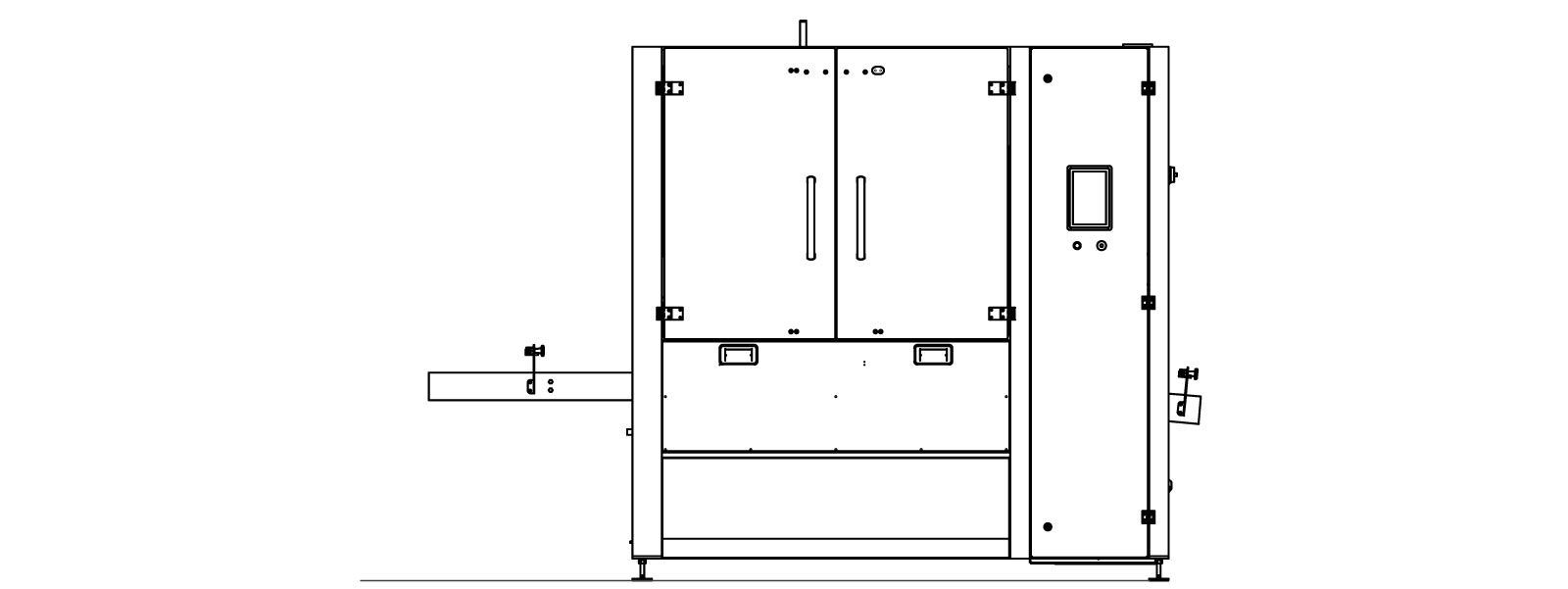

- compact dimensions: 2,2 m x 1,4 m x 2,3 m

- simple tooling change over, which takes approx. 3 minutes and does not require using any additional tools

- operation on packaging with various sizes (from 100 to 1000 ml)

- design with acid resistant stainless steel, safety glass and plastics not susceptible to breakdowns shields assuring safety

- prepared to work with application PackOS

- cheap and easily available format parts made in 3D printing technology (more information about this method can be found here)

- output capacity approx. 40 pcs./min. (2 400 psc./h)

Sorting machine Flexi Pucker 40 was developed having in mind the ergonomic production. This goal was achieved by application of modern process solutions. Machine is equipped with Scara robot, Epson modex LS6 (4-axis, with reach of 600 mm), container for packaging – extending its independent operation time from 10 to 40 minutes, as well as internal indicator lamps. Mechanical settings are changed automatically, while the system is designed in such way as the exchange of component would be as simple as possible. This causes that the device is ideal in situation of frequent tooling change over, while the quick emptying mechanism during format change improves its effectiveness.

Reduced number of manual operations and software with relevant work statistics allow for increasing the capacity of equipment and production improvement. Machine is equipped with visual system, fulfilling also the function of initial quality control and because of that deformed or damaged packages are not fed over to the next production processes.

DO YOU REQUIRE A QUOTE OR A CONSULTATION?

We are more than happy to send further details to you by e-mail