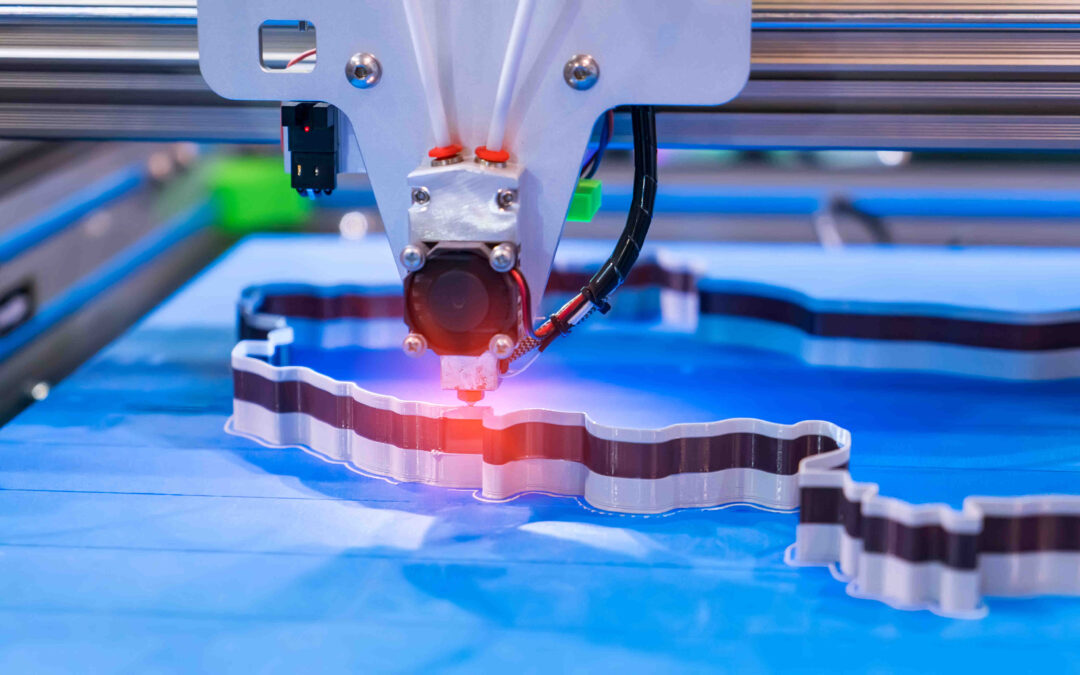

The popularisation of 3D printers in industry has made it much cheaper and easier to quickly produce even very complex components. Nowadays, 3D printing is also widely used in industry and in the manufacturing of industrial machinery.

Table of contents:

What is industrial 3D printing?

3D printing is a modern method of quickly producing parts and components of almost any shape. Parts are produced with a 3D printer by applying layer-by-layer the printing material from which the component is constructed. 3D printing is primarily associated with plastics, but 3D printers are now being used to print components from steel and other materials.

Unlike conventional manufacturing methods such as milling or turning, 3D printing does not result in waste material. With conventional methods, production starts with a semi-finished part that is much larger than the target part. Excess material in the form of chips is removed by machining tools, and this is treated as waste. This type of loss does not occur with 3D printing, as material is added in layers rather than removed.

Various types of printing techniques and materials are leading to 3D printers being used more and more in industry with each passing year. Until recently, 3D printing was treated mainly as a method for rapid, inexpensive prototyping before manufacturing a component using conventional methods. However, due to the continuous development of 3D printing methods and equipment, 3D-printed components are finding more and more applications in various industries.

Advantages of industrial 3D printing

One of the main advantages of 3D printing in industry is the rapid prototyping we have already mentioned. It is useful for both completely new products and modifications to existing ones. 3D printers in industry allow a component to be designed or an assembly to be checked and changed cheaply and quickly. Very often, a prototype component is made as a print, which only goes to the production line for conventional manufacturing after being tested and verified.

The application of 3D printing in industry also makes it possible to significantly speed up the component manufacturing process. As 3D printing does not require specialised cutting tools or machine set-up to produce a part, it is possible to speed up the production process. For companies that do not have an extensive machine park, having a 3D printer allows them to quickly produce the part they need at a given time, which can reduce the downtime of a machine that has broken down, for example.

What other opportunities does 3D printing offer? The industrial nature of this manufacturing method is further emphasised by the ability to make parts with highly complex geometry. Producing such parts with conventional methods usually requires an advanced and expensive CNC machine.

With a 3D printer, complex part shapes are no challenge, which is why 3D printing is used, for example, to manufacture the format sockets of Unilogo’s Futureproof 120 line. The versatile nature of this line means that it can be adapted to produce new types of products very quickly. This is made possible by the format elements made using 3D printing technology.

As we mentioned earlier, the 3D printer is also a huge help for any maintenance department. If a machine part is not immediately available following a breakdown, in the case of simple components a replacement can be produced very quickly, allowing the machine to function until the actual replacement part is delivered.

Applications for 3D printing in industry

Where is 3D printing used? Industrial printing takes place today in many different fields and industries, including manufacturing in its broadest sense. Components from 3D printers are used by designers to check and test various solutions, and by production workers, who use various types of holders for the tools they use, etc. All this is in addition to the possibility for the maintenance department to make spare parts quickly.

Advanced industries, such as aerospace, are also benefiting from the advantages of 3D printing. It is now possible to print from materials that meet the very stringent requirements of the aerospace industry. Parts printed from plastics are lightweight yet strong, making them an alternative to heavier metal parts, although metal-printed parts are also used. 3D printing also allows for the rapid production of the manufacturing and measuring tools used in the aerospace industry.

3D printers are used in the automotive industry as well. Their primary function is prototyping, as we have mentioned, which automotive companies use to launch each new model on the market. However, there are no 3D-printed parts to be found in the cars for sale. With the huge scale of production in the automotive industry, it is more cost-effective to use injection-moulded plastic parts.

However, the manufacturers of all kinds of car accessories, such as various add-ons and other decorative elements, are making use of 3D printing technology. Printed parts are also appreciated by enthusiasts of vintage cars, for which parts are either very difficult or impossible to find. Thanks to 3D printing, it is possible to quickly and relatively cheaply reproduce parts which are not available on the market.

3D printing in industry. Summary

Although 3D printing technology is relatively new, it is now firmly established in most areas of industry. Industrial 3D printing is constantly evolving, resulting in new printing methods and materials. For example, it is already possible to print parts from steel.

In the future, the development of 3D printers is likely to make 3D printing even more precise, cost-effective and time-saving. As a result, more and more companies and industries will benefit from its advantages with each passing year.

Would you like to equip your factory with state-of-the-art production machines with, for example, format slots made using 3D printing technology? If so, we invite you to use the contact form on our website and check out the range of machines from Unilogo. Our advisors will be happy to answer all your questions about manufacturing process automation and help you choose the best solution for your company.