Client: polish producer of professional cosmetics for beauty salons, SPA and esthetic medicine:

– Dermocosmetics

– Cosmetics for home care (body care): creams, balms, cosmetic make-up remover (two phase), shower gels, etc.

Take a look at the movie of the filling line for this client:

Read about the issues our client presented encountered and see how we helped him resolve them.

Challenges:

19 different types of packages (to include plastic bottles and glass jars)

Package capacity: from 25 ml to 1000 ml.

Large variety of densities and viscosities:

- A line for dispensing and filling cosmetics of different densities and viscosities: filling facial creams, body balms and butters (viscosity ranges: 35-79 000 cP)

- Filling watery, non foaming cosmetics: tonics and body mist (viscosity range: from .89 – 1.79 cP)

- Filling shower gel (viscosity range: 14-18 000 cP)

- Filling emulsifiers and two phase cosmetic make up removers: oil and water based products (viscosity range: below 100 cP)

What we recommended:

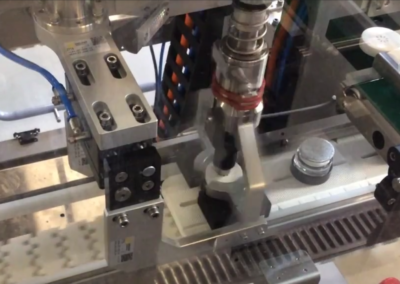

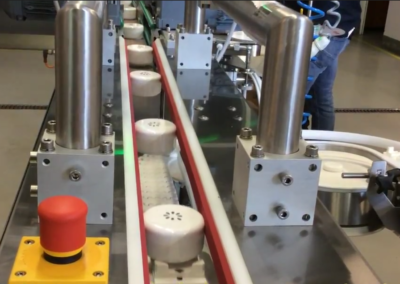

Servodriven piston technology – capable of working a wide range of dosing amounts and variety of product consistencies:

Using servodriven pistons allows filling to occur just below the surface of the liquid, and prevents foaming (in the case of shampoos, soaps, and other highly foamy substances). It also allows the possibility of dosing multiphase products and creating “mixes” i.e. Pouring different color products in one cycle.

Piston dispensing of creams. Supports a wide range: products in liquid and semi-liquid states. Easy cleaning and quick changeover: the dispenser can be removed for washing while a second dispenser that is prepared can be hooked up and begin filling. This simplifies the process of cleaning and retooling.

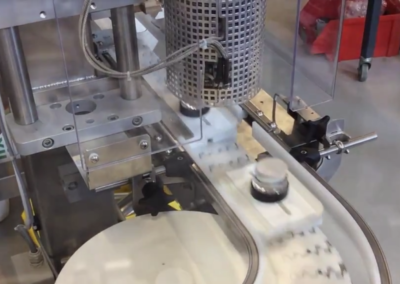

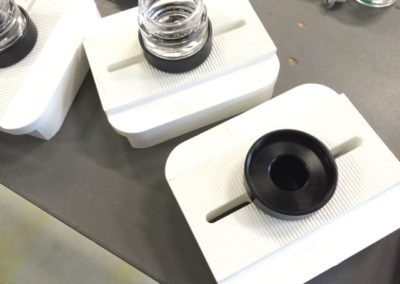

Ability to support small series production – quick and easy changeover to EVERY type of packaging. Using format molds is fast and convenient from one package to the next

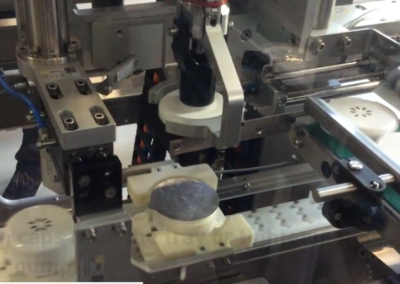

Easily replaceable centering formats ensure that bottle position remains correct throughout the process. The closing nut is equiped with a thread and fed from the feeder using pick & place (applied to traditional flat caps for cream jars).

This was critical when taking into consideration the specific type of closure used in the cosmetics industry: lids for creams are often very delicate, gilded, and metallic. Proper closure provides effective sealing and aesthetics of the packaging, which translates into an effect of the purchasing decision for ens result customers (when distinguishing the product on the shelf. Our closing process does not cause any damage (scratches) on the delicate jar covers.)

An automatic process, the filled and capped packages move down a conveyor to the labeler. In this case the specific labeler was a ROTO – for labeling round containers. Depending on needs, our lines can be retrofitted in any configurations. Examples include flat bottle labeling, two labels – front and rear, and top and bottom labeling.